Plasma cutting is a process of cutting metals (aluminum, steel, copper etc.), while using a plasma arc. It is carried out mechanically or manually. Mechanized cutting processes mainly concern cutting using CNC cutters or industrial robots.

Plasma cutting is an effective way of cutting thin and thick materials alike. Hand-held torches can usually cut up to 38 mm (1.5 in) thick steel plate, and stronger computer-controlled torches can cut steel up to 100 mm (4 in) thick.

Plasma cutting is often used in fabrication shops, automotive repair and restoration, industrial construction, and salvage and scrapping operations. Due to the high speed and precision cuts combined with low cost, plasma cutting sees widespread use from large-scale industrial CNC applications down to small hobbyist shops.

The plasma arc results from heating compressed air electrically and at a very high temperature. This in turn, ionises its atoms and enables them to conduct electricity.

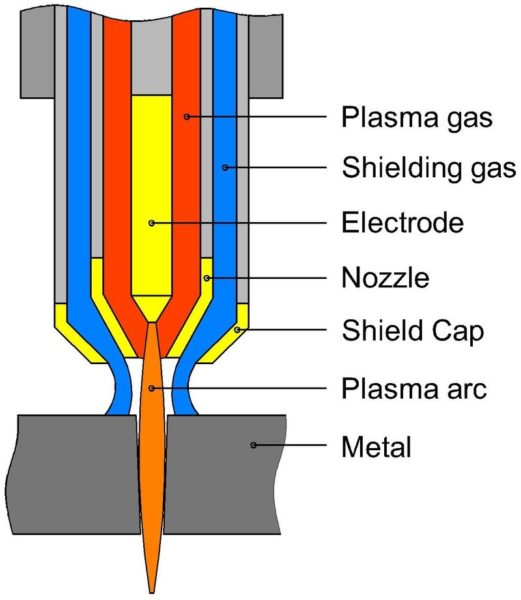

A plasma cutting torch uses a copper nozzle through which the gas stream with the arc is transferred at a very high velocity to the workpiece. The metal cutting operation is achieved by the high temperature and velocity. Actually, the heat generated by the arc melts the metal, while the gas jet removes the molten metal from the cut. The plasma jet can reach temperatures of up to 20,000 degrees celsius. Shielding gases are used for protection. Common shielding gases are helium, nitrogen, argon, or a mixture of these gases. Refer to figure below that shows a schematic representation of the plasma arc cutting process.

Nozzle, electrode and shield cap life is limited by the number of arc starts, not cutting time.

Plasma arc cutting can also be carried out under water using specialised equipment.